This airport is a regional hub airport in East China. The construction of the automated baggage handling system started in December 2021 and the system was officially put into use by the end of 2022. This project is the first case in China to use a linear cross belt sorter to achieve fully automated baggage sorting.

System processing capacity

Total equipment length

The airport has an annual passenger throughput of nearly tens of millions. During peak sorting periods, the airport sorting center cannot meet the demand through manual sorting.

As a complex regional hub airport in East China, the airport incurs high costs in operations, equipment maintenance, and energy consumption. It urgently needs to reduce O&M costs by improving equipment automation levels and digital management technology.

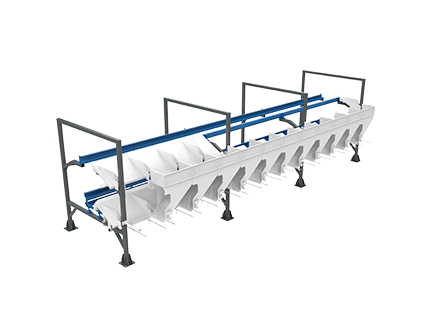

The automated baggage handling system uses a linear cross belt sorting system to solve the problem of limited sorting space, making the equipment highly compatible with the site and achieving efficient automated baggage sorting. The system consists of the departure system and control system, with a total length of about 475 m and the system processing capacity 1,500 pcs/h.

Departure system: includes the standard baggage departure system, linear cross belt sorting system, and camera recognition system for baggage tags.

Control system: includes the electrical and control system, information processing system, equipment monitoring system, and video monitoring system.

The Linear Cross Belt Sorter uses an end-point infeed method and forms a linear sorting mode, with a system processing capacity 1,500 pcs/h.

The sorting carriers actively output baggage through belt operation and the height difference between the carriers and the sorting receiving points is small, sorting baggage flexibly throughout the process with zero damage.

The advanced baggage handling system and the improved management level and efficiency of digital operations can greatly reduce O&M costs and obtain considerable benefits.